Single side

Feature

- Superior dimensional stability under high Temperature

- Excellent flexural endurance/MIT

- Small change rate of peel strength under high temperature

- Made wide range of product structure 1/4oz~1oz cu and various PI thickness

- Green material/Halogen-free and Phosphorous-free

Characteristic

| Property | Spec | 2NUSR 1318 | 2NUSR 2018 | Test Method | |

|---|---|---|---|---|---|

| Product structure | ----- |  |

----- | ||

| Thickness of total (um) | ±10 % | 31 | 38 | ----- | |

| Peel Strength (kgf/cm) |

As Received | >1.0 | 1.20 | 1.25 | IPC-TM650 2.4.9 |

| Solder Float (288 ℃,30S) | 1.05 | 1.10 | |||

| After Aging (200 ℃,1HR) | 1.20 | 1.15 | IPC-TM650 2.3.2 |

||

| Chemical Resistance (MEK,10 min) |

1.15 | 1.10 | |||

| Flexural Endurance (Times) |

M.D. | >1000 (H0Z) | >1500 |

>1200 |

JIS-C 6471 0.8mm radius 0.5kg weight |

| T.D. | |||||

| Tensile Strength (kgf/mm2) | >15 | >20 | >20 | IPC-TM650 2.5.19 | |

| Elongation (%) | >20 | >20 | >20 | ||

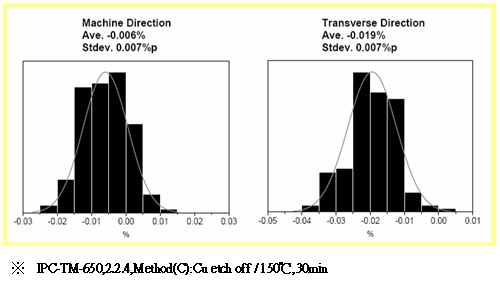

| Dimensional Stability (%) | ≦ 0.1 | -0.050(B) -0.080(C) |

-0.050(B) -0.080(C) |

IPC-TM650 2.2.4C |

|

| Solder Resistance | 340℃×10S | Pass | Pass | IPC-TM650 2.4.13 | |

| UL Flame Class | ----- | 94V-0 | 94V-0 | UL | |

※ Dimensional stability (B)After Etching test (C) 150℃/30min test

※ The feature value of the product is a representative value, not a specification value.

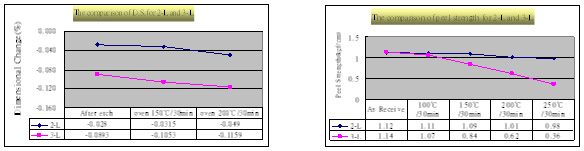

Product feature contrast curve (The comparison of the properties for 2-L and 3-L)

Production specifications list

| Type | Item | PI Flim (um) |

Glue AD(um) |

Copper (um) |

Width (mm) |

Length (m) |

Core Diameter | |

|---|---|---|---|---|---|---|---|---|

| Single Side FCCL | ED Copper | 2NUSE1309X | 13 | - | 9 | 250 or 500 | 100 | 3 inches |

| 2NUSE0812X | 8 | - | 12 | 250 or 500 | 100 | 3 inches | ||

| 2NUSE1312X | 13 | - | 12 | 250 or 500 | 100 | 3 inches | ||

| 2NUSE2012X | 20 | - | 12 | 250 or 500 | 100 | 3 inches | ||

| 2NUSE1318X | 13 | - | 17 | 250 or 500 | 100 | 3 inches | ||

| 2NUSE2035X | 20 | - | 35 | 250 or 500 | 100 | 3 inches | ||

| 2NUSE2518X | 25 | - | 17 | 250 or 500 | 100 | 3 inches | ||

| 2NUSE2535X | 25 | - | 35 | 250 or 500 | 100 | 3 inches | ||

| RA Copper | 2NUSR1318X | 13 | - | 17 | 250 or 500 | 100 | 3 inches | |

| 2NUSR2018X | 20 | - | 17 | 250 or 500 | 100 | 3 inches | ||

| 2NUSR2518X | 25 | - | 17 | 250 or 500 | 100 | 3 inches | ||

| 2NUSR2535X | 25 | - | 35 | 250 or 500 | 100 | 3 inches | ||

| 2NUSR5035X | 50 | - | 35 | 250 or 500 | 100 | 3 inches | ||